Nettuno Irrigation

Nettuno: Italian Manufacturer Since 1976

We have been producing self-propelled irrigation systems and high-quality motor pumps for over 40 years. The reliability and versatility of Nettuno's products come from using the best components and the latest technologies, which provide significant energy savings and reduce operating costs. Our global experience, gained under diverse and challenging environmental conditions, enables Nettuno to fully meet the needs of modern agriculture, while ensuring full respect for the environment.

Nettuno Headquarters - Fontanelle (TV)

Manufacturing Area 5.000 m2

2 Test Room + 1 Test Open-Area Zone

From consultancy to design, from installation to maintenance, the Nettuno team is dedicated to providing a highly personalized service. We deliver products that guarantee exceptional performance and the most suitable solutions.

OUR APPROACH:

- Using the highest quality components;

- Incorporating the latest energy-saving technologies to reduce operating costs;

- Offering unique and original designs;

- Providing hot-galvanized and innovative accessories;

- Ensuring fast delivery times;

- Delivering expert customer support: from project design to final installation;

- Offering efficient after-sales service.

Tecnical consultancy

Nettuno's highly qualified technicians are ready to assist you in finding the most suitable solutions to technical aspects, projects, or business challenges related to water management.

Custom manufacturing

From quotation and design to production, we manage the entire process to deliver a product tailored to your specific needs.

Worldwide Service and shipping

We deeply care about our products and customers, that’s why we offer multilingual technical support and expert logistics to assist you anywhere in the world.

Video:

NETTUNO IRRIGATION is the water department of VISA S.p.A. Generating sets

Nettuno® is a registered trademark of the prestigious Visa S.p.A. industrial group, a global leader in the energy generation sector. With many years of experience in managing complex industrial machinery and a production process focused on high-quality products, we have developed the Nettuno water division, specializing in liquid handling.

We are a team of dedicated professionals with a strong sense of belonging, committed to delivering high-quality services and ensuring reliable solutions for your business.

Nettuno Production Philosophy

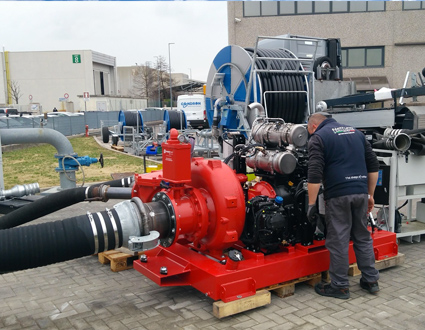

Nettuno (Water Department of Visa SpA) specializes in manufacturing irrigation machines, electro and motor pump sets for agriculture, industry, construction, and emergency applications. It also excels in producing metal frameworks for industrial projects. The company has dedicated divisions for each type of metalworking, supported by precision machinery: sheet cutting, bending of high-strength sheets, carpentry, welding, assembly, and painting.

Video:

Quality Of Service

Visa S.p.A. provides fast and efficient after-sales service for irrigators, motor pumps, and electricity generators, both of its own production and those from other manufacturers. Highly qualified technical personnel, advanced training facilities, mobile workshops, and a spacious area dedicated to the stock of production components enable Visa S.p.A. to respond promptly wherever needed.

Lean Manufacturing Project

The LEAN MANUFACTURING process is a philosophy and method for driving innovation. This system has been implemented in the VISA production cycle to improve work phases and reduce delivery times while maintaining high-quality standards. The assembly islands have been organized based on the size of irrigators and motor pumps, designed to enhance efficiency in line with the continuous improvement process.

CERTIFICATIONS

ISO 45001:2023 - HEALTH AND SAFETY MANAGEMENT SYSTEMS

Visa SpA is now ISO 45001:2023 certified. This standard specifies “the requirements of a management system for the HEALTH and SAFETY of workers.” Achieving this certification is an important acknowledgment granted by an accredited third-party body. The certification demonstrates Visa SpA’ s dedication to creating safe and healthy workplaces by preventing work-related injuries and illnesses and proactively improving its occupational health and safety performance. The primary objective is to improve safety and safeguard the health of both employees and external personnel. The certification already incorporates the A1 update, which addresses actions related to climate change.

ISO 14001:2015 – ENVIRONMENTAL MANAGEMENT SYSTEMS

Visa SpA plant is certified ISO 14001:2015. The system defines specific monitoring and control procedures, assigns clear roles and responsibilities and maintains active communication among the interested parties as well as with the competent Authorities. In compliance with the requirements of the Environmental Management System, every year the production plants define suggestions and processes to improve environmental performance. The provisions defined at the Group's sites are of great importance to ensure immediate action in situations of potential environmental emergency. They guarantee a prompt reaction in the event of an accident in order to avoid or to minimize the environmental impact. The latest certification renewal already incorporates the A1 update regarding actions relating to climate change.

ISO 9001:2015 – QUALITY MANAGEMENT SYSTEMS

Visa SpA is ISO 9001:2015 certified. The standard specifies “requirements for a quality management system when an organization needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements, and it aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements”. The latest certification renewal already incorporates the A1 update regarding actions relating to climate change.

EN 1090

EN 1090 certification, certifies a company’s ability to produce materials that meet all the quality requirements of the standard.This type of certification allows, for example, to be able to mark CE our structural steel products and to sell them and work in Europe and abroad.

ISO 3834 - WELDING PROCESS

ISO 3834 defines the quality requirements for welding for fusion of metallic materials. Among the objectives of the standard are: to ensure the company’s competence in the welding process, to guarantee to customers the conformity of the products manufactured, and to safeguard workers during the work phases.

ETHICAL AND SOCIAL RESPONSABILITY

Visa SpA undertakes to operate in compliance with the respect of the human rights, of the rights and professionalism of its employees, to guarantee a healthy work environment to protect the health and the safety of people who work there.

THE ATTENTION TO THE ENVIRONMENT AND THE HEALTH AND SAFETY OF WORKERS IS PART OF COMPANY POLICY

In all our activities we strive for the preservation of our environment by spreading a corporate culture characterized by a strong environmental awareness. At the same time we strive to ensure that there is the utmost attention to the health and safety of workers. For this reason we wanted to integrate our commitment to the environment and to worker safety into the "Company Policy" document.

231 MODEL - ORGANIZATION, MANAGEMENT AND CONTROL

In carrying out its activities, the Company has always been inspired by a model of behavior marked by maximum transparency and strict compliance with laws and regulations.

VISA SpA has therefore considered it appropriate to analyze and strengthen all the control and governance tools already in place and has proceeded to the adoption and implementation of the Organization, Management and Control Model provided by the Legislative Decree No. 231/2001.

In view of the above, we inform you that the Board of Directors of VISA SpA, on May 31, 2024, decided to adopt the Organization, Management and Control Model pursuant to Legislative Decree 231/2001, also appointing the Supervisory Board, which endowed with autonomous powers, has the task of ensuring compliance with the protocols and procedures contained in Model 231.

Some examples:

About

Nettuno Irrigazione has been producing high-quality self-propelled irrigation systems and motor pumps for over 40 years.

Reserved Area:

MYPOWER: Register your machine to access all digital documents LINK

WEBSUPERVISOR: Remote control through the portal LINK

VIDEO AREA: Our channel with videos and tutorials of Nettuno products LINK

Contact info

- VIA I MAGGIO, 55

- FONTANELLE (TV)

- From Monday to Friday: 8:00 AM - 6:00 PM

- Call Now!

- nettuno@visa.it